Create Your Space: Teamwork Makes the Dream Work

By Katherine Verano in Community, Real Estate, St. Kitts

Have you ever wondered what it’s like to live the island life? In this series, “Create Your Space,” we share a glimpse of the people, places, and life that make Christophe Harbour and St. Kitts home. We'll also share some expert insight into how to create a space that you can call your own, whether you're visiting, shopping for a Caribbean vacation home, or settling into a new beachfront home permanently. Today's wisdom comes from John MacDonald, Principal of architectural design firm Morehouse, MacDonald & Associates, and Russell Fortenberry, Residential Construction Manager of Bennett Hofford Caribbean Construction Company, on the importance of a strong design-build team and what it takes to create a successful space.

From design to build, there are many different methods for creating the right “space.” What’s your approach?

John: A team approach from the very beginning, one where you’re all putting your expertise out on the table at the same time. Don’t fragment the professional services needed to provide a successful project. By doing so, you create a situation of one step forward, two steps back.

Russell: The team approach is the key. If you don’t have the whole team in place from day one, you won’t have the successful project that you’re looking for. It’s that simple. Hire everyone upfront and have them all around the table from the beginning of the project. It might seem obvious, but trust me, it’s not, and it will cost everyone time and money. An 18-month project can quickly become a 32-month project, and those kinds of delays cause tension, animosity and frustration.

A few classic examples are where the client hires the landscape architect after the house has been built only to realize the house needed to move forward to accommodate the Zen garden. Or, when the interior designer is hired after the house is framed, and the client’s furniture doesn’t fit into the space. Had everyone been on the same page from day one, the architect and builder could easily customize the space to fit the Zen garden and the furnishings without sacrificing design.

Tell me about this team approach. How does it work when you have team members who may be in different countries or time zones?

Russell: Communication and planning. It’s important to manage expectations. Not every architect or builder can envision this or envision that and just make it work. You need to think out of the box here in the Caribbean and plan far enough ahead to give yourself time for success. When you have a team that is firing on all cylinders, we’re able to communicate properly with the client, to make sure they understand that there’s a balance between budget and program. The worst thing you can do is to underestimate build cost or build time.

John: Yes, communication is a big piece of the puzzle, and so is time and patience, you need all three for a successful project. The more we talk, the more we work together, the better we are. Everyone understands the process, and by having conversations early, you’re collaborating. The architect is typically the ring leader, but if the builder or landscape architect is adamant that something won’t work, I listen to them. And of course, we all listen to the owner. They can trump anything!

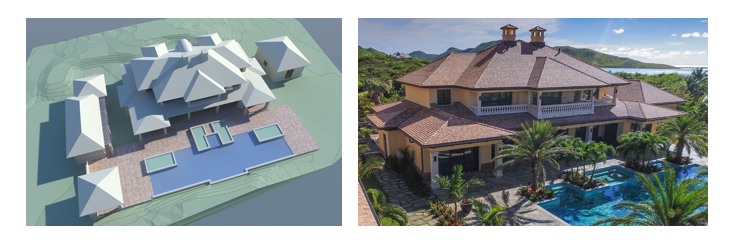

Some clients want to be extremely involved, others are incredibly trusting and very hands-off. There are many layers to making this process work, and it’s always a push and pull situation to juggle budgets and site constraints. We use a lot of 3D modeling to help the client understand exactly what they’re getting and avoid “I didn’t know this is what it would look like” or “I didn’t want that material” after construction has begun.

Russell: Another important thing is having the right subcontractors. I’ve worked with some of my subs for 25 years. They’re loyal and dedicated, and I can depend on them to be there to back me up. I’m only as good as my people, and having guys who have worked with me for nearly three decades is like having another set of eyes. People ask me why it looks so easy, and I say it’s all about my people. We also have a great local staff that have been trained by the most experienced subs in the most important trades of masonry, carpentry, and electrical. They are very committed and very loyal to us. When you find the right fit, the team sticks like glue.

Sustainability is very on-trend. As an architect and builder, how do you fit “environmentally responsible” and “resource efficient” into your projects?

John: Well, I think sustainability and performance go hand-in-glove. As far as sustainability is concerned, there are certain things that we do architecturally to take advantage of the setting: the views, the trade winds, the sun’s location throughout the day as well as incorporating hurricane proof materials. Everything is in the walls. Or, in other words, seamlessly integrated. But it takes time to incorporate intelligently and at a price point that everybody is comfortable with. Another part of the sustainable equation is using products that you know are going to hold up in the Caribbean. You don’t realize how invasive salt can be, so using maintenance-free products like mahogany and stucco are key. Certainly though, there are some fashionable sustainable materials out there like bamboo flooring, for example, most of which comes from Malaysia. The footprint to get from there to here is much bigger than people realize. We talk a lot about how we can use materials that are within a reasonable radius of St. Kitts and Nevis.

Russell: When I first got here, I met two guys who’d been building here on this island for many years. They’d tried every kind of product on the market, but kept returning to what works here. And that’s block and concrete, a great example of the quality and craftsmanship we have access to right here in St. Kitts. Why use an alternative? That goes for other materials that we use purposefully because they’re nearby like plantation stone from Nevis, mahogany from Honduras, Caoba windows and doors from Guatemala, Wallaba roof shingles from Guyana. I also get all my coral stone, rebar and steel from the Dominican Republic and use a local shop for my handrails and millwork. All products we know are going to hold up and stand up and will eliminate maintenance down the road.

Building in the Caribbean brings a different set of opportunities and challenges. How has this affected your work?

John: For me, the best part is that I get to broaden my experience, use different materials and solve for different challenges. It just makes me a better architect. We’ve been very fortunate, that every time I turn around its a new experience, new client, new opportunity. Working with Russell and his team has been a dream. It makes my life easier. Having someone that can execute makes all the difference in the world. When you’re doing this for a living and you love what you do – it sure doesn’t feel like work.

Russell: Being able to live here and do amazing work here has been such a positive. Everyone wants to live in the Caribbean, and I have certainly taken full advantage of that, to say the least. I always considered myself a good builder at Kiawah Island, where I worked prior to Christophe Harbour, but I’m a far better builder down here. And that’s mainly because of the planning that is a necessity here. I have had to adapt because planning and shipping takes much more time here. I have to plan far ahead to order it, get it unloaded and prepared so we can make our schedules. Planning just makes the building process so much easier. Its taking my work to another level in building to be out in front of the job and making the right moves to stay on schedule. Sometimes you have to think out of box to make it work, but we live and die by the schedule.

John: The bidding process is also another challenge. We don’t have the option of bidding out three electricians in the Caribbean. And in some cases, you don’t have any options. For example, we have a metalsmith onsite now who is creating some custom water pieces for one of our clients. We’re also working on a complicated, cantilevered stair that no one here was capable of doing. It’s highly specialized work, and learning curves cost the client money. So, we used our shared experience and trusted relationships to find someone we can collectively count on to do the job right. If we can save time in project duration, we are saving far more money than we are in a 10% differential between electricians.

Another factor of building here is building a home that can withstand the elements, which can be harsh. How do you manage for this?

John: Coastal environments are naturally tough environments, and we take the precautions that are mandated by the international building code and then add to it. Hurricane shutters and hurricane-rated windows are worth the extra cost – as is the right kind of reinforcement, the right kind of construction and engineering. We’re no longer planning for the 100-year storm; we’re planning for the 500-year storm. We are fortunate here at Christophe Harbour to have the mountains for protection. The hillside is a wonderful, naturally occurring protective presence, especially at Upper Pavilion Hill. I’d say the presence of that mountain behind you is one of the most valuable components of building a home there. It’s a strong argument to use the hillside to your advantage.

Russell: We’re building to be prepared for storms – big and small. Like John said, we use the mountain to our advantage and think strategically about drainage needs. Nothing is completely air tight or waterproof, but our goal is to find ways to mitigate that and funnel it out and around the built environment. Stop, divert, protect. That’s the what we do.

Because Christophe Harbour is primarily a second-home community, most owners live thousands of miles away from the property. How do you make the building process easier for absentee owners?

Russell: We have live cameras running 24/7 on all of our houses when we’re building. So a client can always see the production of their home from wherever they are in the world. Not only that, but I also do a weekly progress report with detailed photos every Friday.

John: We recommend that clients come down periodically to check on the progress of their homes in person, but technology certainly makes it easier to have face-to-face meetings throughout the building process. It’s also very helpful to coordinate travel schedules to be here onsite when the client is. It’s easy when you’re nearby, but good communication, good drawings, good pricing, good methods are all key. It doesn’t take long to gain a client’s trust, but once you lose it, it takes a long time to get it back.

Russell: That’s right. It really comes down to doing your job, and doing it well, and not hiding the issues. If we have issues with a home, we put it on the table right then, and communicate it out to everybody.

Homeowners have wildly different styles, influences, tastes – how do you synthesize it into a space that works?

John: Every client is different, and every piece of land is different. There are so many things to consider, and you really have to design to the land, customize and tailor to the slope, the topography, the views, the orientation. Take Pavilion Hill for example, we have good Eastern exposure and good Southern exposure, so we want to take those spaces and study how they live from morning until night. Then we start applying how the sun and wind affect the site, the views. Where do you want to be first thing in the morning, or at sunset? All of this plays into how the design will eventually articulate, and it’s important to do this study before ever applying architectural license. How does it all look? How does it fit into the context of the neighborhood and environment and the region?

Russell: We’ve traveled to Bali and hired Feng shui consultants – two things I can say I’d never done before Christophe Harbour – and learned different cultures and styles. It’s very rewarding getting to meet clients from literally all over the world - Bermuda, Russia, Israel - and closer to home – Texas, Tennessee, New York. It’s forced us to adapt to the little things that clients want to incorporate into their homes due to their cultural style or upbringing. It’s expanding everyone’s horizons and has been really fun to bring that experience to bear in some pretty incredible Caribbean homes.

Any parting thoughts for those who may be considering building their Caribbean dream home here at Christophe Harbour?

Russell: We have really qualified, really competent resources here. There are several good builders, architects and landscape architects who know the region, know the landscape and have the experience it takes to make your home a reality. Don’t be afraid of the construction process.

John: This is not your normal cookie cutter build and design experience. Take full advantage of your team’s collective experience. They will provide good advice and sound guidance that will save you time and money in the long run.